Hydromacht is a well known brand of Hydraulic Rock Breakers in India. It is a one stop solution to all your needs concerning Hydraulic Rock Breakers. Hydromacht is known for its power, efficiency, reliability and has a proven track record in the industry.

Hydromacht Breakers is available in variety of sizes and models which is suitable for base machines ranging from 0.7 ton to 100 tons. With our high quality and excellent services records, we are the first choice in the field of Hydraulic Rock Breakers used for Mining and Heavy Machineries Equipment Market.

Hydromacht Breakers can withstand continuous breaking in harsh and extreme environments. Higher strength allows us to use plate steels construction, i.e. you get the highest quality in breakers and the power to weight ratio and the efficiency is also increased drastically.

Hydromacht Breakers find its use in variety of applications

- Secondary Breaking in Mining or Quarrying applications

- Breaking in demolition

- Trenching

- Preventing blockage in Crushing Systems

And many more heavy, tough and time critical applications.

Features:

- HM hydraulic breakers have 12 ranges of operating weight from 100kg to 7,000kg suitable for base machines up to 90 tons such as Skid Steer Loaders, Backhoe Loaders & Excavators.

- Air intake system offers long service life for major consumable parts such as bushings & retaining pins due to proper lubrication & air cooling during operation.

- Variety of options for different applications (Auto Grease System, Underwater Kit, Soundproof Kit, Tunneling Kit & Water Jet Kit).

- Unique design for housing bracket along with damping systems prevents damage of excavator & free maintenance operation.

- The selector system for Auto Stop & Auto Idle is providing less trouble & maintenance cost even in tough conditions jobs.

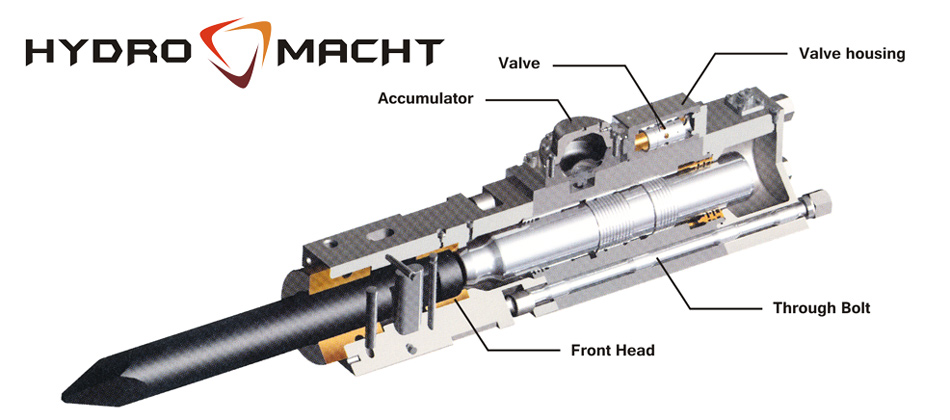

- Extended durability, efficiencies & service life, with low cost maintenance and trouble free. Higher impact rate and low vibration thanks to new design of through bolts & piston.

Specifications:

| Descriptions | HM 10 | HM 30 | HM 50 | HM 60 | HM 120 | HM 160 | ||

|---|---|---|---|---|---|---|---|---|

| Operating Weight | KG | 135 | 178 | 345 | 425 | 920 | 1,260 | |

| Overall Height |

with mounting bracket | mm | 1,000 | 1,350 | 1,390 | 1,370 | 2,290 | 2,516 |

| without mounting bracket | mm | 1,000 | 1,190 | 1,390 | 1,370 | 2,020 | 2,150 | |

| Operating Pressure | bar | 80-110 | 90-120 | 95-130 | 100-130 | 150-170 | 160-180 | |

| Required Oil Flow | lpm | 20-30 | 25-40 | 30-45 | 40-80 | 80-110 | 90-130 | |

| Impact Rate | bpm | 600-1,200 | 500-1,000 | 450-750 | 450-950 | 450-800 | 300-900 | |

| Tool Diameter | mm | θ45 | θ53 | θ68 | θ75 | θ100 | θ120 | |

| Hose Diameter | inch | 1/2" | 1/2" | 1/2" | 1/2" | 3/4" | 3/4" | |

| Recommended Base Machine | tons | 0.7-1.5 | 1.0-3.0 | 3.0-7.0 | 5.0-9.0 | 9.0-14.0 | 13.0-19.0 | |

| Descriptions | HM 220 | HM 230 | HM 320 | HM 420 | HM 520 | HM 720 | ||

|---|---|---|---|---|---|---|---|---|

| Operating Weight | KG | 1,590 | 1,735 | 2,460 | 2,730 | 4,450 | 6,910 | |

| Overall Height |

with mounting bracket | mm | 2,754 | 2,830 | 2,951 | 3,280 | 3,770 | 4,320 |

| without mounting bracket | mm | 2,374 | 2,560 | 2,531 | 2,850 | 3,230 | 3,860 | |

| Operating Pressure | bar | 160-180 | 160-180 | 160-180 | 160-180 | 160-180 | 160-180 | |

| Required Oil Flow | lpm | 135-180 | 120-180 | 160-220 | 190-250 | 250-310 | 350-450 | |

| Impact Rate | bpm | 300-650 | 350-500 | 200-500 | 200-450 | 150-350 | 120-320 | |

| Tool Diameter | mm | θ135 | θ140 | θ150 | θ160 | θ180 | θ200 | |

| Hose Diameter | inch | 1" | 1" | 1¼" | 1¼" | 1¼" | 1½" | |

| Recommended Base Machine | tons | 18.0-25.0 | 18.0-26.0 | 28.0-36.0 | 32.0-45.0 | 45.0-65.0 | 62.0-85.0 | |